Giới Thiệu Hệ Thống Cáp Quang của OHTL

1. Prysmian’s fibre optic systems forOHTL – always the right decision

Because OHTL networks are critical assets in any country, the best-performing and safest materials must always be used in their creation.

Customers who choose Prysmian systems are choosing solutions that are proven to succeed in terms of installation and operation. In economic terms, that means no unexpected costs due to on-site delays, professional project management throughout the supply process and true longevity of the technology installed.

2.The main advantages of Prysmian’s solutions include the following:

High reliability and proven experience

We have installed over 195,000km of highly reliable cable, with OPGW systems in operation since 1983 in more than 100 countries in all five continents.

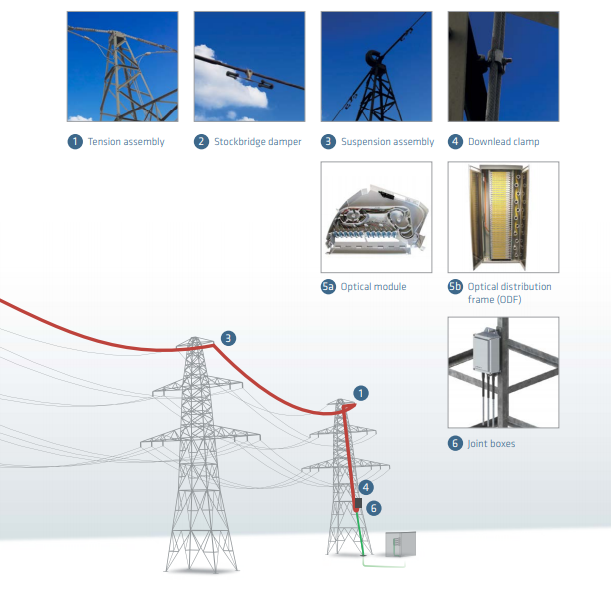

Supply of all components, guaranteed system

Prysmian guarantees the compatibility of its systems, while supplying all materials from end to end:

- - 100% Prysmian Group fibre

- - Aerial cables and terminal cables

- - Joint boxes, optical distribution frame and connection accessories

- - Components for securing the cable to the towers/poles

- - Engineering and installation services, with turn-key projects

- - Robots and tools for installation

- - Customised drum lengths

Manufacturing capabilities

Prysmian has a growing production capacity of more than 25,000km of OPGW cables per year in three different continents; Europe, America and Asia.

OHSAS 18001 and ISO 14001

Prysmian Group is involved in implementing management and production processes which help improve environmental sustainability and safety at work, in accordance with the guidelines of its HSE policy

ISO 9001

The Prysmian brand has always been a guarantee for the supply of products and services based on common worldwide quality standards. Prysmian has a built-in multi-step quality assurance programme, which covers the entire production process from cable design and raw materials purchasing, to final inspection and testing documentation.

Full range of technologies

Because we own all of the required technology, we provide every customer with the most appropriate and relevant technical solution for any single project. Prysmian Group never has a pre-determined answer to a challenge – instead, we always recommend the best solution on a case-by-case basis.

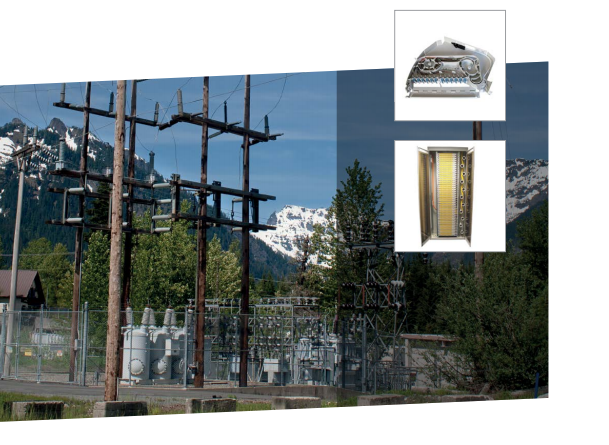

2.1 Complete solution for the integration of telecommunications networks on high voltage overhead lines

2.2 OPGW extruded aluminium cable

Superior corrosion resistance

- Meets IEEE construction guidelines for use in high corrosion sites

Superior electrical performance

- Aluminium core tube substantially increases conductor cross-section

- Improved short-circuit capacity

Superior lightning resistance

- Fewer Aluminium Alloy (AA) wires are needed to meet electrical specifications

- More/heavier duty ACS wires can be used

- AA wires can be completely replaced with ACS in some applications

High performance in high fibre counts

- - All fibres are housed in the core tube

- - Core tubes are available in a wide range of inside diameters

- - Armour wires are not replaced with fibre tubes in high count designs

- - Electrical and mechanical properties can be maintained

Prysmian’s extruded aluminium OPGW provides increased conductivity without sacrificing tensile performance, lightning resistance or fibre count.

2.3 OPGW stainless steel tube embedded in extruded aluminium technology

Stranded stainless steel tube

- - Wire strands are replaced with fibre-filled stainless steel tubes

- - Fibre tubes are helically stranded alongside the wires

- - Fibre strain margin is increased relative to core tube designs

- - Loaded sag can be increased without placing fibres under strain

Compact design

- - Reduced weight

- - Increased flexibility

- - Smaller minimum bend radius

- - Easier to handle and install

- - Lower wind and ice loads put less load on structures

Prysmian’s stainless steel OPGW cable with the SST in the lateral position allows cable elongation and sag to be increased without increasing fibre strain. It is best suited to applications where the ground wire will be replaced by an identical cable due to tower limitations. Because of this, OPGW contains exposed elements made of both stainless steel and aluminium. It should therefore not be used for high corrosion sites.

2.4 OPGW – Spiral Space® technology

Superior corrosion resistance

- - Dissimilar metals are prevented from reacting with one another

- - Provides performance without risk of galvanic corrosion

- - Meets IEEE construction guidelines for use in high corrosion sites

High performance in high fibre counts

- - All fibres are housed in the core tube

- - Excellent heat protection of fibres

- - Armour wires are not replaced with fibre tubes in high count designs. Electrical and mechanical properties can be maintained

Prysmian’s OPGW cable with Spiral Space® technology consists of a unique Spiral Space unit for optical fibres. The fibres are loosely buffered in a tube containing an oval, spiralling, hollow channel filled with jelly. The loose tube construction prevents fibre strain at any stage of installation or operation. This ensures a long, stress-free fibre life.

The Spiral Space® construction allows the use of a high fibre count in a single small-diameter tube.

Optical fibres

With over 20 years’ experience of manufacturing optical fibres, Prysmian Group is able to offer an extensive product portfolio designed to achieve the highest levels of quality and performance. This is thanks to our unique position of having access to the major manufacturing processes: MCVD (Modified Chemical Vapor Deposition), OVD (Outside Vapor Deposition), VAD (Vapor Axial Deposition) and PCVD (Plasma-activated Chemical Vapor Deposition). This enables Prysmian Group to obtain an optimised range of products for different applications.

Single-mode fibre ITU-T G.652.A/B and IEC 60793-2-50 B 1.1

Single-mode fibre (SMF) provides optimum performance in both the 1310nm and 1550nm wavelength operation ranges (including the 1565 – 1625 nm L-band), with a low dispersion in the 1310nm window. It can be used in all cable constructions and supports long haul, metropolitan, access and premises applications in telecommunications, CATV, utility and intelligent traffic networks.

Single-mode fibre ITU-T G.652.C/D and IEC 60793-2-50 B 1.3

Enhanced single-mode fibre (ESMF) provides improved performance across the entire 1260nm to 1625nm wavelength spectrum. It has a low dispersion in the 1310nm window and low attenuation in the 1383nm water-peak region to allow use of the extended band (1360nm to 1460nm). With its wide operating spectrum, ESMF expands the future growth capability of the fibre and allows flexible configuration of voice, data, and video services within the fibre. It can be used in all cable constructions.

Single-mode fibre ITU-T G.652.C/D and IEC 60793-2-50 B 1.3, with lower cabled loss

Enhanced single-mode fibre (ESMF) with lower secured cabled loss in all the transmission bands, including the highest ones (L and U-bands), intrinsically more sensitive, provides further improved and secured performance across the entire spectrum; such premium attenuation levels inside the finished cable, even in demanding environments, are offered through superior microbending resilience of the fibres used while still preserving all parameters and characteristics of G.652.C/D fibres, made possible using a fine-tuned glass optimisation combined with the use of a highly performing protective coating

Single-mode ITU-T G.655.C/D and IEC 60793-2-50 B 4_c/d

Non-Zero Dispersion Shifted Fibres (NZDSF) designed for DWDM applications. They are characterised by relatively lower dispersion values from 1530 to 1625nm, compared to G.652 fibres. They are available in two grades, to cover a variety of transmission challenge optimisations: one version with large effective area (NZDSF-LA) to contain the generation of non-linear effects during propagation, and another version with reduced chromatic dispersion slope (NZDSF-RS) to equip a broader range of channels with the benefits of a lower dispersion.

Single-mode ITU-T G.656 & G.655.C/E and IEC 60793-2-50 B 4_c/e & B5

NZDSF with Medium Dispersion values, as described by recommendation ITU-T G.656 and more recently G.655.E, have set the standard for high bit-rate, multi-wavelength transmission. Those fibres are designed with a global transmission optimisation in mind, aiming at containing the detrimental effects of chromatic dispersion whilst at the same time ensuring that the properties of such dispersion still contain the nonlinearities. They offer a unique trade-off between effective area, chromatic dispersion and dispersion slope thus providing an excellent transmission distortion management, cost-effectively; they secure operation at 10, 40 and 100Gbps per channel, tight channel spacing in C- and L-bands, and compatibility with the S-band; a definite step further for long-haul and ultra-long-haul applications.

Prysmian Group’s fibre manufacturing process quality and performance coupled with Proprietary ColorLockXS™ coating process further enhance the performance, durability and reliability of the fibre, even in the harshest environments.

Joint boxes

Stainless steel box

The XOK universal joint closures are designed to provide water and pressure-tight environmental protection for optical fibres and optical fibre splices regardless of the cable design. Application ranges from aerial, duct to buried installations. The closure has anchoring points for strength members and facilities for earthing of metallic elements.

The splice organiser trays offer holders for heat shrink splice protectors and sufficient space for storage of spare fibres. The closure is easily assembled and re-entered.

The closure is available in two sizes: XOK 103 series up to 192 splices and XOK 107 series up to 336 splices. By using extension collars and/or splice trays for fibre ribbons, the splicing capacity can be increased up to 1000 splices.

The closure is available in seven basic configurations with two, three or four cable entrances. XOK A3/A4 branch joint closures and extension collars for more cable outlets are also available. Closures can be delivered as complete installation packages up to 192 fibres.

Dimensions (excl. inlet tubes)

- - XOK 103 series: 560 x 230 x 100mm

- - XOK 107 series: 560 x 230 x 140mm

- - XOK A3 and A4: 560 x 230 x 140mm

Inner diameter of entry ports

- - XOK 103 series: round port 20mm, oval port 58 x 28mm

- - XOK 107 series: round port 27mm, oval port 58 x 28mm

- - XOK A3 and A4: oval port 58 x 28mm

Materia

- - Closure: acid proof stainless steel (AISI 316) 1.5mm

- - Closure seal: chloroprene rubber

Splice tray capacity

- - XOK 103 series: 4 trays XOKP 1024/48 with 48 splices each (192 splices)

- - XOK 107 series: 7 trays XOKP 1024/48 with 48 splices each (336 splices)

- - XOK A3 and A4: 4 trays XOKP 1024/48 with 48 splices each (192 splices)

IP rating: IP68

Aluminium joint box

EWMJ & EWJ joint boxes are specially designed to provide maximum versatility for OPGW cable splicing, which enables their use in OPGW and other optical cable systems. The joint box is made of aluminium alloy and has a maximum capacity of 240 fibre splices. A pre-moulded neoprene anti-ageing gasket, perfectly inserted in the groove of the cover, provides an excellent sealing against dust and water-jets

An assembling plate prepared with fixing devices for the cable and for the splice trays is placed inside the box.

Cable glands and a heavy wall heat shrinkable tube are used for sealing the entries of the OPGW cables. The anchoring of the joint box to the tower is achieved with galvanized steel clamps allowing the fixation in all type of towers, and with stainless steel tape in all type of poles.

- - Maximum number of cable entries: 4

- - Maximum cable diameter (mm): 25

- - Maximum number of splice trays: 8 (EWMJ) – 10 (EWJ)

- - Maximum number of splices per tray: 24

- - Maximum number of splices: 192 (EWMJ) – 240 (EWJ)

- - IP rating: IP67

- - Required space envelope (mm): (l) 319 x (w) 219 x (d) 110. (EWMJ) - (l) 319 x (w) 319 x (d) 175 (EWJ)

- - Operating temperature: -40o C to + 85o C

Material

- - Joint box: aluminium alloy with grey coated powder (RAL 7042)

- - Fastening structure: aluminium and galvanized steel

- - Nuts and bolts: stainless steel

-

Optical Distribution Frame (ODF)

The RS3000 Rack is a standard rack with 19” mounting rails, used to accommodate a range of SRS3000 shelves and sub-racks or any other 19” rack mounted products. The rack is 900mm wide by 300mm in depth and is available in 42U and 47U heights (2000 and 2200mm). The rack is supplied with side panels and transparent doors. Cable brackets are supplied in the left-hand side of the rack to enable a range of cable anchor brackets to be installed.

Mandrels are supplied in the right hand side of the rack to manage and store patchcords. The maximum capacity of the rack is 2160 fibres (based on the 47U rack on a splice + patch basis).

The SRS3000 Splice and Patch Shelf is a modular unit available in a variety of configurations for integration into 19” and ETSI racks, street side or wall-mounted cabinets. The product consists of a metal chassis, a plastic lightweight splice and patch module and a cable anchoring system. The product has a capacity of up to 48 fibres in a 1U unit for SC and LC type connectors, and up to 24 fibres for FC, ST and E2000 type connectors. The panel has in-built fibre management to ensure the product is installed correctly and the same every time by installers.

Kết Nối Với Chúng Tôi

Công Ty TNHH Thương Mại Và Dịch Vụ VIỄN ĐẠT

Copyright © 2019. All Rights Reserved

Trụ Sở Chính : 27 Nguyễn Đình Chiểu, Phường Sài Gòn, Tp. Hồ Chí Minh

Địa chỉ Giao Dịch: 16/2 ter Đinh Tiên Hoàng, Phường Sài Gòn, Tp. Hồ Chí Minh

Điện thoại: 84 28 3911 8909, Fax: 84 28 3910 0929, Email: info@viendat.com